350080, Krasnodar city,

Simferopol street, №62 room 307

Tel/Fax: 8(861) 236-25-50,

236-24-61, (495) 989-23-10

E-mail: t33367@mail.ru

90 deg. elevators КМ, 18 deg. elevators КМК, ЭН,ЭТАД,ЭТА, ЭС, ЭХЛ

SIDE DOOR ELEVATORS КМ YUGMASH Plant LLC informs you that the marking on the elevator tag is done using the dot method with the image of our logo.

DESIGN DESCRIPTION

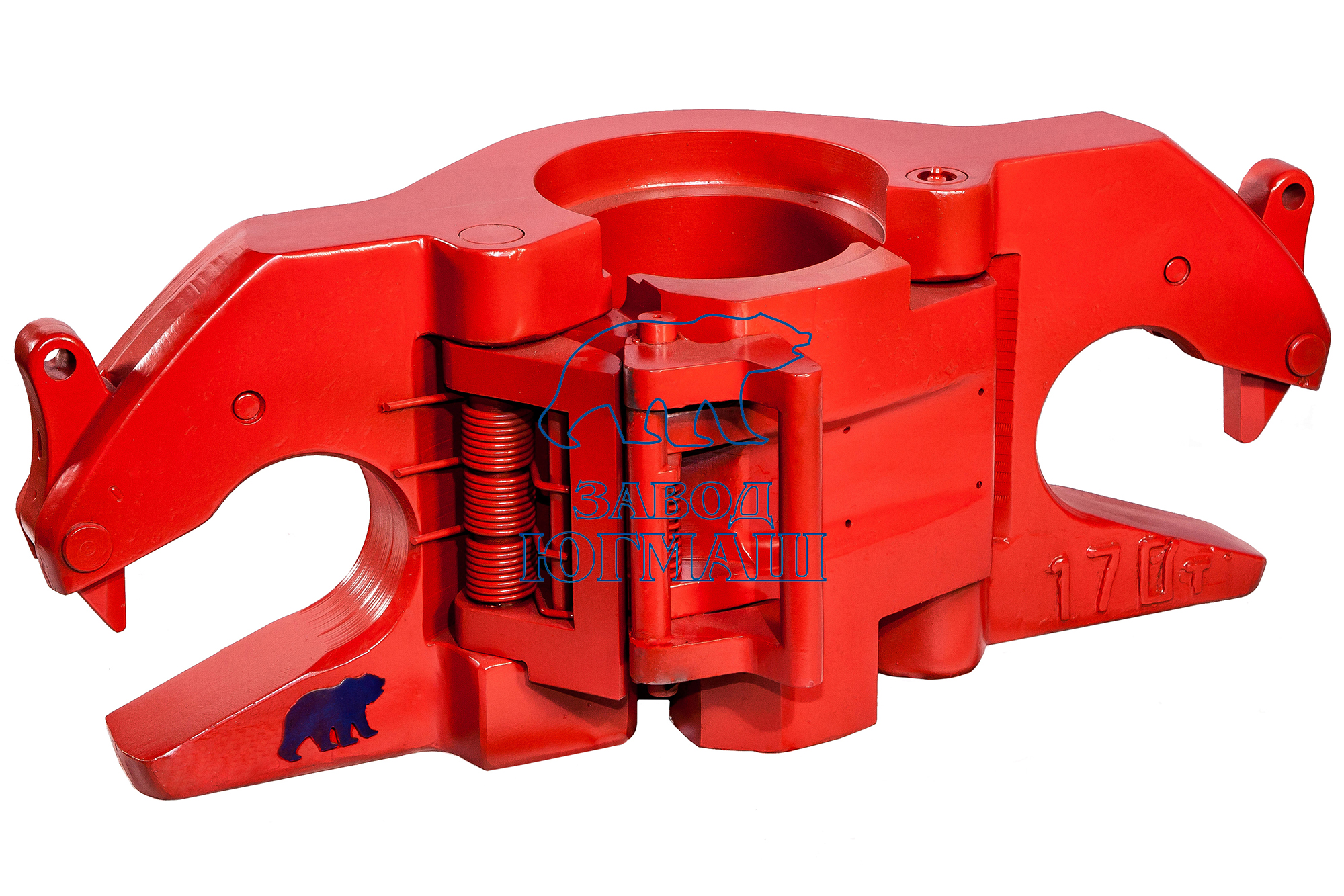

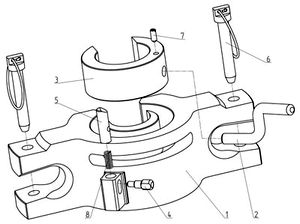

The main parts of the elevator are body 1 and side door 3 made of steel forgings (Figure 1).

The left side of the body has a latch 11 that retains the side door in closed position. Handle 10 is hinged on the side door; when lowered and turned “towards itself,” the latch and the elevator side door open.The upper part of the elevator body has a bore for the pipe coupling, which eliminates the possibility for the pipe coming out of the elevator, if the side door is not tightly closed. Link protectors 6 installed in the elevator eyes ensure free insertion of links into the eyes and prevent them from falling out during operation. The link protectors shall be rotated around the axis to remove the links from the eyes.

Figure 1.

КМ-type elevator: 1 — body; 2 — lock spring, 3 — side door; 4 — handle spring, 5 — link protector spring, 6 — link protector; 7 — link protector axis; 8 — side door axis; 9 — handle axis; 10 — handle; 11 – latch; 12 – latch axis.

DESIGNATION AND TECHNICAL CHARACTERISTICS

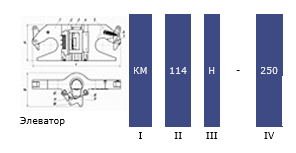

DESIGNATIONS AND EXPLANATION

Elevator type (KM – modernized side door elevator) The conventional designation of the elevator includes:

- Nominal diameter of the latched pipe, mm

- Type of the latched pipe:

- without letters – drilling pipes with internally upset ends and casing pipes;

- Н – drilling pipes with externally upset ends;

- ПН – welded-on drilling pipes with external upset;

- ПВ – welded-on drilling pipes with internal upset;

- Н/НП – drilling pipes with externally upset ends and weld-on integral joints with external upset;

- ПК — welded-on drilling pipes with internal-external upset;

- ПК-У — welded-on drilling pipes with internal-external upset of steel group У;

- НП – drilling pipes with weld-on integral joints with external upset;

- П/НП – drilling pipes with weld-on integral plain joints and weld-on integral joints with external upset;

- Л – light-alloy drilling pipes.

- Maximum lifting capacity, kN (tf)

TECHNICAL CHARACTERISTICS

|

Elevator code |

Lifting capacity, kN (TF) |

Nominal diameter of the latched pipes, mm |

Bore diameter, mm |

Overall dimensions, mm |

Weight, kg |

||

|

L |

В |

H |

|||||

|

KM60-125 |

1250 (125) |

|

63 |

610 |

225 |

250 |

67,0 |

|

KM89-125 |

1250 (125) |

|

92 |

645 |

250 |

250 |

81,5 |

|

КМ114-140 |

1400 (140) |

|

118 |

670 |

295 |

260 |

94,0 |

|

КМ89-200 |

2000 (200) |

|

92 |

710 |

255 |

310 |

120,5 |

|

КМ114-250 КМ114ПК-В-250 |

2500 (250) |

114 |

118 118/131 118/123 118/131 |

760 |

330 |

320 |

155,0 151,0 152,0 149,0 144,0 150,0 |

|

КМ127-250 |

2500 (250) |

|

131 |

760 |

330 |

320 |

149,0 |

|

КМ140-170 |

1700 (170) |

140 146 |

144 |

755 |

325 |

290 |

131,0 |

|

КМ168-170 |

1700 (170) |

168 |

172 |

780 |

345 |

290 |

134,0 |

|

КМ140-320 |

3200 (320) |

140 |

144 |

800 |

340 |

350 |

193,0 |

|

КМ194-320 |

3200 (320) |

194 |

198 |

850 |

390 |

350 |

261,0 |

|

КМ245-320 |

3200 (320) |

245 |

250 |

900 |

435 |

350 |

295,0 |

|

КМ299-320 |

3200 (320) |

299 |

304 |

1020 |

475 |

350 |

340,0 |

|

KM340-320 |

3200 (320) |

340 |

347 |

1070 |

510 |

350 |

363.0 |

|

KM377-320 |

3200 (320) |

377 |

384 |

1100 |

535 |

350 |

395,0 |

|

KM426-320 |

3200 (320) |

426 |

434 |

1180 |

617 |

350 |

442,0 |

Bevel side door elevators КМ(К)

Boring approval sheet SAMPLE KMK elevator

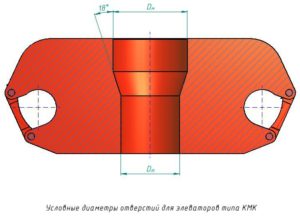

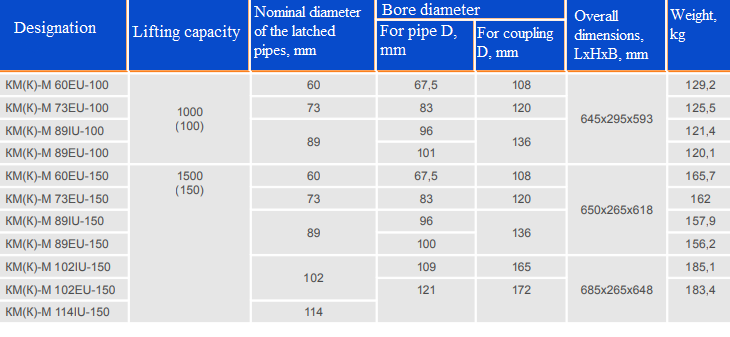

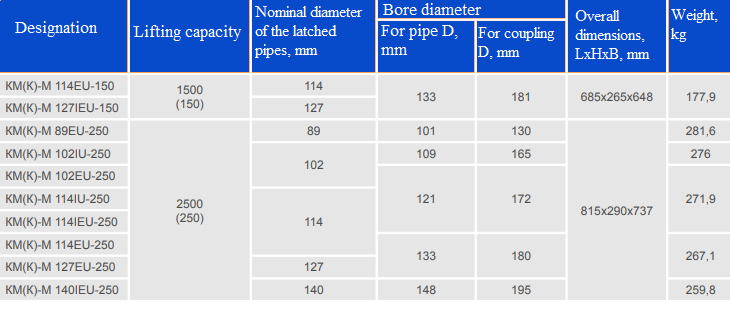

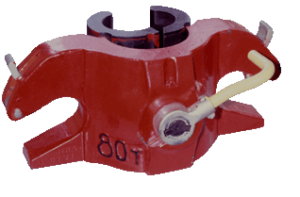

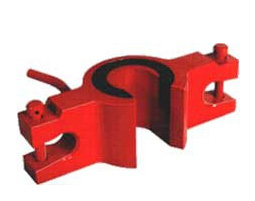

КМ(К)-М-type elevators are designed to latch on and hold suspended drilling strings with a bevel

18о upset,

with a diameter from 60 to 127 mm, at tripping operations during drilling the oil and gas

wells, in moderate and cold macroclimatic regions (region I2) according to GOST 16350–80. Operating category of

the product — I as per GOST 15150-69.

Equipped with a special patented locking mechanism increasing convenience and safety of work

with drilling pipes.

Lifting capacity — 100, 150 and 250 tons.

Drilling pipe diameter — from 60 to 127 mm.

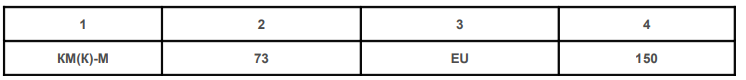

Conventional designations of elevators and pipes used

The conventional designation for each КМ(К)-М elevator includes:

1 – Elevator type

2 – Nominal diameter of the latched type, mm

3 – Type of the latched pipe:

IU – drilling pipes with internally upset ends;

EU – drilling pipes with externally upset ends;

IEU – drilling pipes with internal-external upset.

4 – Maximum lifting capacity, kN (tf)

1 – Elevator type

2 – Nominal diameter of the latched pipe, mm

3 – Maximum lifting capacity, kN (tf)

Technical characteristics and conventional designations of bevel КМ(К) elevators

ЭН-type pipe elevator

ЭН-type elevators are designed to latch on and hold suspended the casing strings at tripping operations during drilling the wells. It is used in moderate macroclimatic region according to GOST 16350-80.

|

|

ЭН-194-160 |

ЭН-219-160 |

ЭН-245-160 |

|

Lifting capacity, t |

160 |

160 |

160 |

|

Nominal diameter of the pipes, mm |

194 |

219 |

245 |

| The hole diameter for pipe, mmThe hole diameter for pipe, mm |

198 |

224 |

250 |

| Overall dimensions, mm |

940х352х365 |

965х382х365 |

995х412х365 |

| Set weight, kg |

180 |

220 |

235 |

|

|

ЭН-325-160 |

ЭН-426-160 |

|

Lifting capacity, t |

160 |

160 |

|

Nominal diameter of the pipes, mm |

325 |

426 |

|

The hole diameter for pipe, mmThe hole diameter for pipe, mm |

331 |

433 |

|

Overall dimensions, mm |

1095х502х365 |

1195х602х365 |

|

Set weight, kg |

290 |

354 |

ЭТАД-type elevator

ЭТАД-80 double-link pipe elevator with automatic locking device is designed to latch on under the coupling or lock, and hold suspended tubing or drilling strings at tripping operations, both with vertical installation of pipes, and with laying them on walkways during development and workover of oil and gas wells. The elevator is designed for use in moderate and cold macroclimatic regions in accordance with GOST 16350-80.

|

|

ЭТАД-80 |

|

Lifting capacity, t |

80 |

|

Nominal diameter of the pipes, mm |

73, В73, Н73, 89, В89, Н89, 102, В102, 114, В114, Б89 |

|

Overall dimensions, mm |

510х310х220 |

|

Weight, kg. |

96 |

ЭТА-type elevator

|

Code |

Max. lifting capacity, tf |

Nominal diameter of the latched pipes, mm |

Bore diameter for the pipe, mm |

Overall dimensions, mm, max. |

Weight, kg, max. |

|||

|

length |

width |

height |

with maximum latch on |

of full set |

||||

|

ЭТА-32 |

32 |

48, В 48 60, В 60 73, В 73 |

50, 56 62, 68 75, 81 |

280 |

200 |

540 |

19 |

34 |

|

ЭТА-50 |

50 |

60, В60 73, В73 89 |

62, 68 75, 81 91 |

290 |

230 |

575 |

28 |

36 |

|

ЭТА-60 |

60 |

60, В 60 73, В 73 89 |

62, 68 75, 81 91 |

300 |

240 |

590 |

33 |

41 |

ЭС-type elevator

Single-link ЭС-type elevators are lifting devices designed to latch on the strings under the coupling or lock and hold them suspended at tripping operations during the development and workover of oil and gas wells.

Elevators are designed for operation in cold and moderately cold microclimatic regions according to GOST 15150-SS at temperatures from — 50 to + 40 °С

| Characteristic | Lifting capacity, t | Weight of the full set, kg, max |

| ЭС-32 | 320 (32) | 25 |

| ЭС-50 | 500 (50) | 28 |

| ЭС-60 | 600 (60) | 44 |

| ЭС-80 | 800 (80) | 44 |

ЭХЛ-TYPE ELEVATORS

ЭХЛ-type elevator is designed for lifting, holding suspended and running of tubing

GOST 633-80 and drilling pipes

GOST 631-75.

Technical Characteristics

Lifting capacity, t – 8,10,15,25,35

Nominal diameter of pipes, mm – 33,48,60,73,89

Overall dimensions, mm, max.

— length — 340,340,375,375,435

— width — 130,130,155,157,172

— height — 98,98,110,130,150

Elevator weight — 11,85;11,2;20,5;24,15;32,7