350080, Krasnodar city,

Simferopol street, №62 room 307

Tel/Fax: 8(861) 236-25-50,

236-24-61, (495) 989-23-10

E-mail: t33367@mail.ru

Mesh panels with perforated support

Mesh panels compatible with the Derrick FLC 2000/48-30 PWP

Technical characteristics:

- Material:stainless steel 304/316/316 L.

- Construction type:PWP (perforated mesh plate).

- Shape of perforated plate cell:rectangular/hexagonal.

- Designation API RP 13C:API 120 – API 400.

- Size:1050 × 695 mm.

- Weight:4.6 kg.

- Series:DX, DF, HP (optionally).

- Package:2 pcs in a cardboard box, packed in a wooden box.

Shaker screen panels SJ-PWP 2000, also known as 48-30 meshes, are similar to the Derrick FLC (Flo-Line Cleaner) 2000 series screen panels. They are fastened flat mesh plates made of multiple layers of 304 or 316 stainless steel wire mesh. Further the screen plate is attached to a perforated metal sheet with rectangular or hexagonal cells in order to provide additional support and the possibility of repairs.

Compatible screen panel models

SJ-PWP 2000 screen panels are used for

- Three-panel shaker screen Derrick FLC (Flo-Line Cleaner) 2000.

- Four-panel shaker screen Derrick FLC (Flo-Line Cleaner) 2000.

- Shaker screen Derrick 48-30.

- Mud cleaners Derrick FLC (Flo-Line Cleaner) 2000.

- Shaker screen Derrick FLC Plus, FLC with dryer AWD, HI-G.

Competitive advantages:

- Manufactured according to standard API RP 13C (ISO 13501).

- High quality stainless steel wire mesh with long service life.

- Increases the shaker screen performance and reduces mud losses.

- Scientific and research approach and reasonable cost control system at competitive prices.

- Higher throughput without violating the integrity of the fraction boundary.

- Sufficient amount of inventory to satisfy the Customer’s needs in the shortest possible time.

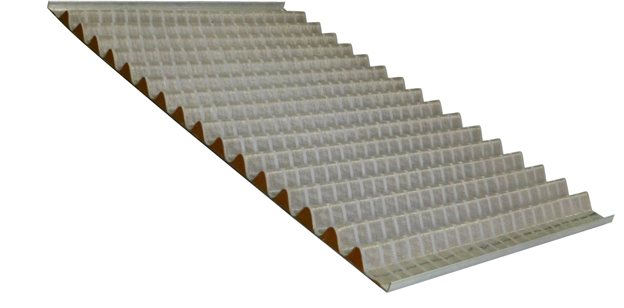

Screen panels compatible with the Derrick FLC 2000/48-30 pmd

Technical characteristics:

- Material:stainless steel 304/316/316 L.

- Construction type:PMD (pyramidal).

- Mesh cell shape:rectangular.

- Designation API RP 13 C:API 20–API 325.

- Size:1050 × 695 mm.

- Weight:5.6 kg.

- Series:DX, DF, HP (optionally).

- Package:2 pcs in a cardboard box, packed in a wooden box.

SJ-PMD 2000 screen panels are manufactured using Derrick Corporation’s innovative designs. The design of this screen panel model includes several layers of stainless steel wire mesh of varying densities. If these layers are chosen reasonably and precisely, the end result can be a screen panel with a revolutionary three-dimensional corrugated structure. Unlike traditional flat multi-layer screen panels, pyramid-shaped mesh increases the usable area by up to 125-150%. The fluid throughput also increases.

Compatible screen panel models

SJ-PMD 2000 screen panels are used for

- Three-panel shaker screen Derrick FLC (Flo-Line Cleaner) 2000.

- Four-panel shaker screen Derrick FLC (Flo-Line Cleaner) 2000.

- Shaker screen Derrick 48-30.

- Mud cleaners Derrick FLC (Flo-Line Cleaner) 2000.

- Shaker screen Derrick FLC Plus, FLC with dryer AWD, HI-G.

Competitive advantages:

- Conforms to standard API RP 13C (ISO 13501).

- Resistant to corrosion, high temperatures and mechanical impacts.

- Larger area and higher conductivity.

- Increases the shaker screen performance and reduces mud losses.

- Scientific and research approach and reasonable cost control system at competitive prices.

- Higher throughput without violating the integrity of the fraction boundary.

- Sufficient amount of inventory to satisfy the Customer’s needs in the shortest possible time.

Screen panels compatible with the Derrick FLC 500 series pwp

Technical characteristics:

- Material: stainless steel 304/316/316 L.

- Construction type: PWP (perforated mesh plate).

- Mesh cell shape: rectangular.

- Designation API RP 13 C: API 20 – API 325.

- Size: 1050 × 695 mm.

- Weight: 6.2 кg

- Series: DX, DF, HP (optionally).

- Color: green.

- Package: 2 pcs in a cardboard box packed in a wooden box.

Flat screen panel FLC 500 is intended to replace the screen panel of Derrick FLC 500 series shaker screen. Includes two to three layers of 304 or 316 stainless steel wire mesh assembled together on a steel support plate. FLC 500 PWP screen panel features a one-way quick-release tension control system, which helps to reduce panel replacement time.

Compatible screen panel models

SJ-PWP 500 screen panels are used for

- Shaker screen Derrick FLC (Flo-Line Cleaner) 503.

- Shaker screen Derrick FLC (Flo-Line Cleaner) 504.

- Drying shaker screen Derrick FLC (Flo-Line Cleaner) 503.

- Drying shaker screen Derrick FLC (Flo-Line Cleaner) 504.

- Shaker screen Derrick FLC (Flo-Line Cleaner) 513.

- Shaker screen Derrick FLC (Flo-Line Cleaner) 514.

- Shaker screen Derrick FLC (Flo-Line Cleaner) 513 VE (Vapor release).

- Shaker screen Derrick FLC (Flo-Line Cleaner) 514 VE (Vapor release).

Competitive advantages:

- 304/316 stainless steel wire mesh with long service life.

- Quick-release tension control system, excellent trapping effect (waste removal).

- Simple system for checking, removing and installing the mesh.

- Increases the shaker screen performance and reduces mud losses.

- Scientific and research approach and reasonable cost control system at competitive prices.

- Higher throughput without violating the integrity of the fraction boundary.

- Conforms to standard API RP 13C (ISO 13501).

- Sufficient amount of inventory to satisfy the Customer’s needs in the shortest possible time.