350080, Krasnodar city,

Simferopol street, №62 room 307

Tel/Fax: 8(861) 236-25-50,

236-24-61, (495) 989-23-10

E-mail: t33367@mail.ru

Cassettes for domestically produced vibrating screens and analogues for imported vibrating screens

The mesh plate consists of two meshes: working mesh with a specified cell size for separation, and a coarse mesh, which acts as support and bears physical loads. They are used for main and coarse separation (according to the international classification – TBC).

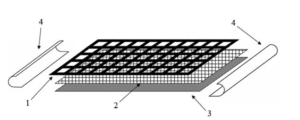

A sketch of the screen

1 – frame lattice;

2, 3 – substrate mesh and filtering mesh;

4 – mounting profile.

Mesh panels with perforated support

Panels with pyramidal mesh plate

Mesh plate

For the production of our screens, only mesh made of stainless steel grade 12Х18Н10Т is used. In industry, this steel grade is used for products operating at temperatures up to 600°C, in diluted solutions of nitric, acetic, phosphoric acids, alkalis and saline solutions at high pressure, as well as within the temperature range from -196 to +600°C, and at presence of aggressive media up to +350°C.

Chemical composition in % of material 12Х18Н10ТC Si Mn Ni S P Cr Cu –

up to 0.12 up to 0,8 up to 2 9-11 up to 0,02 up to 0,035 17-19 up to 0,3 (5°С-0,8) Ti, the rest is Fe

The flexibility of our production allows us to produce screens with any standard size and mesh cell size in accordance with the data listed in the table.

| Cell size | Wire diameter | Mesh |

| 0,042 | 0,036 | 325 |

| 0,056 | 0,35 | 280 |

| 0,064 | 0,032 | 264 |

| 0,074 | 0,05 | 205 |

| 0,08 | 0,055 | 188 |

| 0,094 | 0,055 | 170 |

| 0,1 | 0,066 | 153 |

| 0,12 | 0,09 | 120 |

| 0,125 | 0,09 | 118 |

| 0,14 | 0,11 | 100 |

| 0,16 | 0,12 | 90 |

| 0,2 | 0,13 | 76 |

| 0,25 | 0,16 | 60 |

| 0,4 | 0,25 | 40 |

| 0,55 | 0,28 | 30 |

| 0,8 | 0,32 | 23 |

| 0,9 | 0,32 | 20 |

| 1,2 | 0,14 | 15 |

| 1,6 | 0,4 | 13 |